Squeaking sounds were coming from my CR-10 Mini for months until I realized the cause. It was the timing belt; x-axis belt to be specific. I was hoping that all I needed to do was look for a CR-10 Mini replacement belt online and change the belt. I felt I would not have an issue with the process after watching two videos on Creality’s YouTube channel. The exact length of belt I needed was not readily available anywhere, meaning I would need to cut and crimp the belt myself. That was not something I was looking forward to doing. At the time, I was unaware of how essential timing belts were to obtaining good prints.

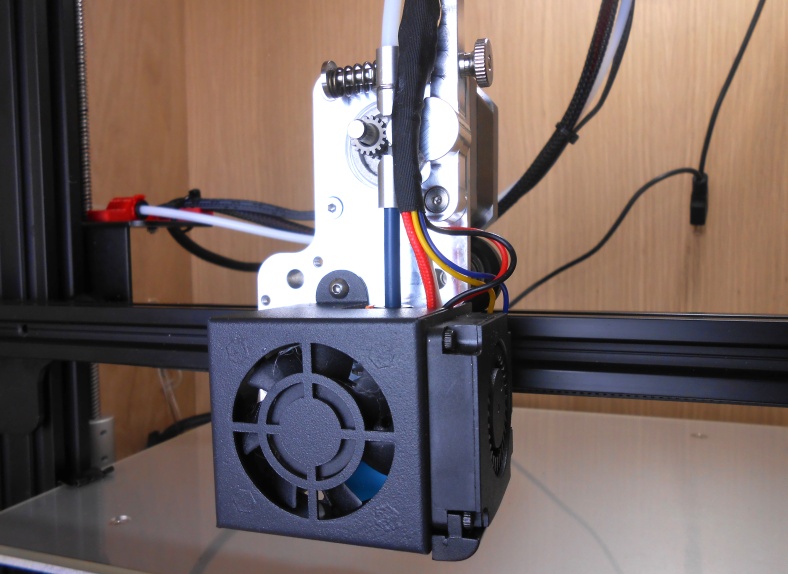

Continue reading “The Missing Piece of My Extruder Upgrade”